Tig Welding Settings Chart

Thus the Tig can also be used to weld stainless steel aluminum etc.

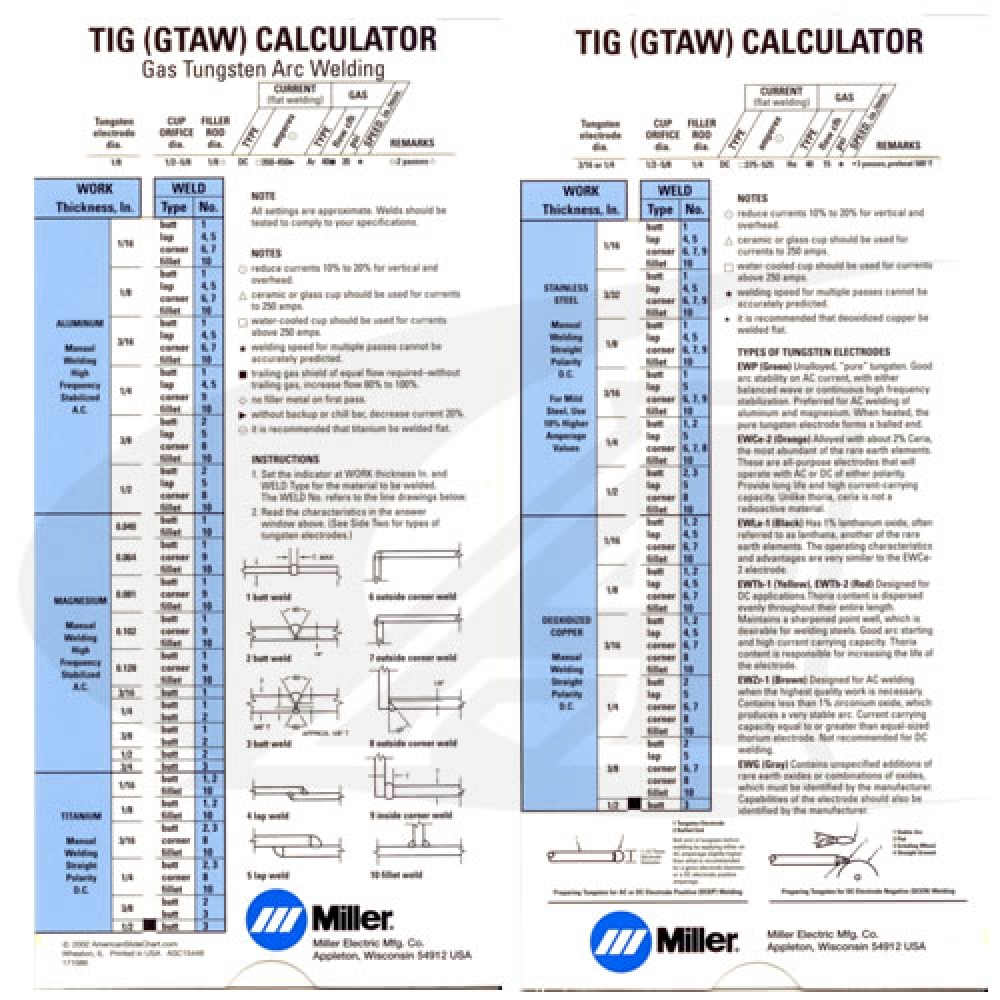

Tig welding settings chart. For Pulse Settings - set pulse width 60 peak current 185 background current 125 Hz 10 MS or SS. If you like our calculators please free to share them with your friends and visit our other useful Pro Welder Guide posts. They are amperage and gas flow.

The voltage is used to fine-tune the power source of a MIG welder. TIG welding requires three main things. Nearly sixty years of experience have gone into producing these premium quality TIG welding tungsten electrodes and you benefit from that experience.

Easier to use products through auto-settings and better visibility. Further information on the TIG Welding Process follows information on equipment used in this document. Basic TIG Settings for GTAW.

Tig Tungsten Inert Gas generates the heat from the arc which is the electricity of the arc. Heat gas and filler material. Here is a chart that summarizes the MIG welding amps according to the three most common types of metal and their thickness.

Tungsten inert gas welding Principles Tungsten inert gas shielded welding is usually called TIG welding. 32mm one amp per one thousandths thats about 40 amps per mm. Cagnazzi Racing relies on Millers Dynasty 200 TIG welder for precise TIG welding in the fabrication of NHRA Pro Stock dragsters.

Adequate gas flow for GMAW typically ranges from 35 to 50 cubic feet per hour. To address some of the questions I frequently got asked or was wondering myself during my job I. Amperagepretty straightforwardbut there is a simple rule of thumb that holds true up to about 125 thick metal.

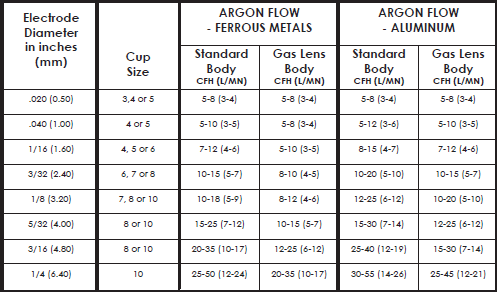

See the chart below for recommended flow rates. It can be run on AC DCEP and DCEN. Last updated on January 28th 2020 at 0101 am.

Optimize your operation through advanced welding processes training and weld data monitoring. TIG Welding Machine Set-Up. Operating the Tig welder is quite a difficult task to do.

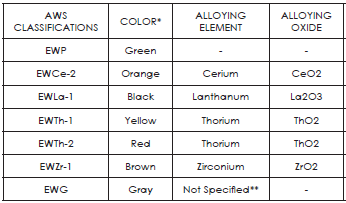

The electrode is not melted and any filler metal needed to build up the weld profile is added separately. TIG Welding Tungsten Electrode Selection Chart Type ACDC Recommended Usage 2 Thoriated Red DC Copper alloys nickel alloys titanium alloys and non-corrosive steels 2 Lanthanated Blue AC DC. Improve productivity with technologies that enhance efficiency and save you money.

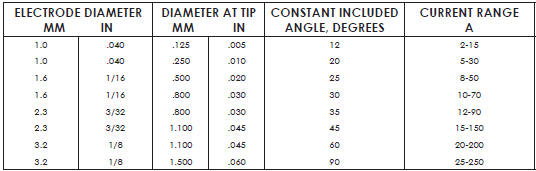

116 Tungsten means youll need amps between 50-100 cup sizes of 4 5 or 6 and a gas flow rate of 5-15 CFH. Tig welding is different from other types of Welding Techniques. Some of the settings that you need to really get a handle on are.

Best Tig Welder For The Money. On some TIG welding machines you may be able to easily adjust the amperage. What Metal are you welding.

Welding Xpert Blog April 4 2018. Apart from the general MIG welder settings chart youll also find an aluminium MIG welding settings chart and a Lincoln MIG welder settings chart that highlight specific products and welding. For Pulse Settings - set pulse width 60 peak current 150 background current 50 Hz 10 316-14 - pre-flow 1 sec hot start 20 amperage 185Hz 60 balance 20 post-flow 80 sec.

With polarity settings in welding you can select where each pole is located and if they change. What Polarity is Suitable for TIG Welding. Way back in the 1930s to 1940s it is being used by the aircraft.

Other Factors that Influence MIG Welding Settings. Below weve included a list that has guidelines for your machine set-up when welding mild steel. Slope Up only used with torch trigger operation Slope Down only used with torch trigger operation Gas post flow adjustment.

Select material Aluminum Deoxidized Copper Magnesium Stainless SteelSteel. Most recently as a Process Engineer for Laser and TIG welding processes. 332 Tungsten means youll need amps between 80-130 cup sizes of 6 7 or 8 and a gas flow rate of 8-20 CFH.

When setting up a TIG welder there are two main settings. What is TIG Welding. Very large cup sizes will require more flow but for the apprentice using about 20 cfh is sufficient.

AC Balance control SP AC Squarewave frequency control. Any of the poles can exist either on the side of the electrode or on the side of the welding area. TIG welding can be carried out using DC for Stainless Steel Mild Steel Copper Titanium Nickel Alloys etc and AC for Aluminium and its Alloys and Magnesium.

So lets talk about the main tig welding inverter settings. E6012 Sizes and amperage range E6013 Size and Amperage Chart. A flow of 15 to 25 cfh will cover most applications.

Both the molten metal in the weld pool the tip of the filler wire and the hot electrode. You just set the amperage to a point that you are comfortable with how fast it melts the metal your welding. E6013 is a High Titania Potassium rod designed for welding sheet metal.

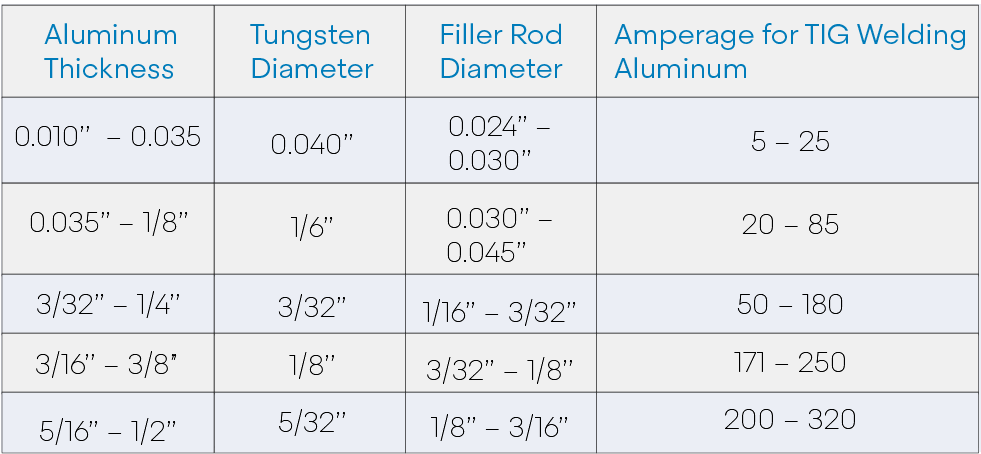

Amperage settings vary depending on the type and thickness of the metal to be welded. GUIDE TO TIG WELDING. The Power Source is of a transformer design with or without a rectifier with a drooping characteristic constant.

Gas shielding to protect the weld from contamination provided through a. Pulse Welding used only on torch trigger operation Remote foot pedal. The rod has low penetration dense slag soft and stable arc while it can be used in all positions it needs clean base metal to weld on.

Heat is created by the electricity going through the welding tungsten electrode thus igniting an arc.