Feeds And Speeds Chart

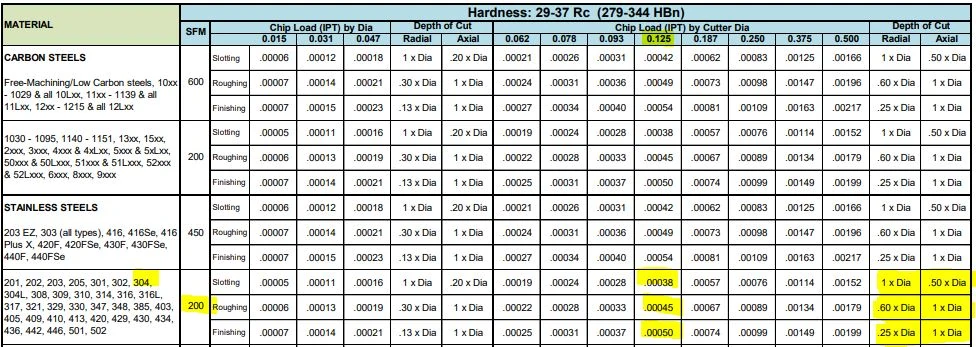

Chip loads are based on the material thickness of average size for the cutting edge length of the tool.

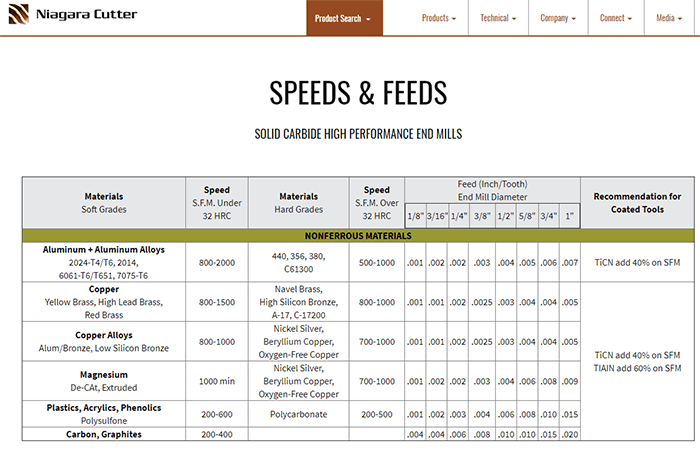

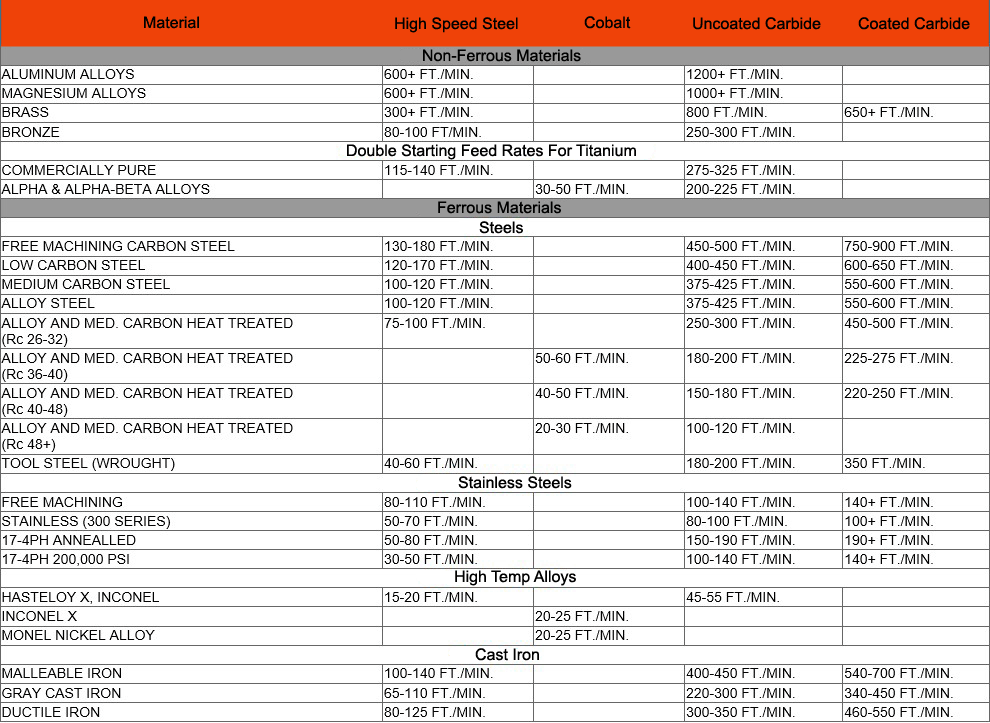

Feeds and speeds chart. Below are the Speeds and Feeds Charts for Rock River Tool products. Whith the above parmeters you can proceed to calculate the Milling Feed Table Feed. Milling Speeds and Feeds.

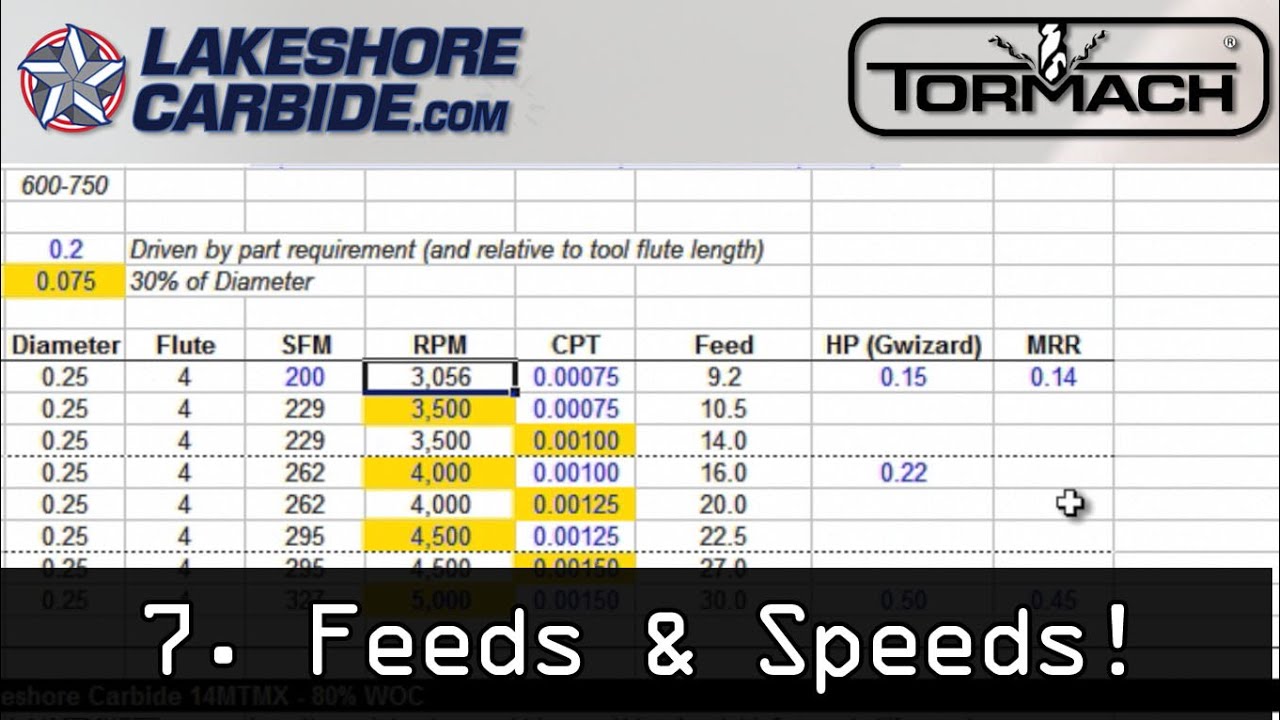

Feeds and Speeds Calculator for CNC machine tools. To learn what is SFM and how to go from SFM to RPM click this link. SFM see table below for SFM values.

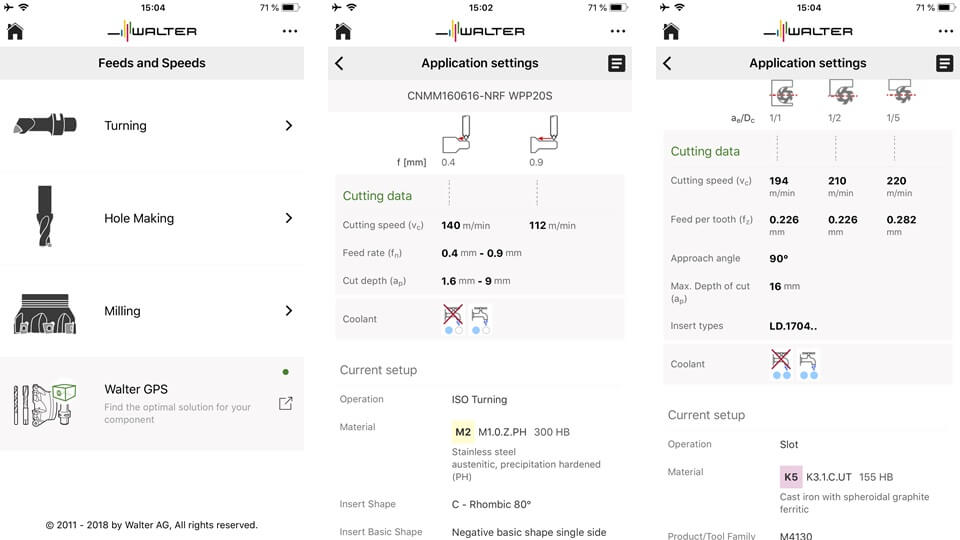

Cutting Speed Get wit with our Speeds and Feeds Calculator or from the tool suppliers catalogwebsite. Keyseat Cutter Speeds and Feeds. Reducing heat prolongs tool life.

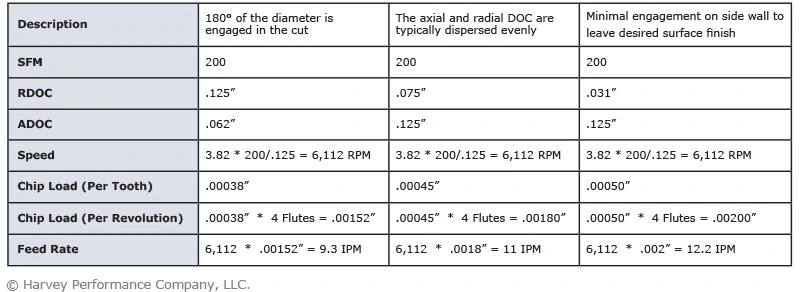

Start off using an RPM derived for the chip load for the. Radial Depth of Cut Ae Depends on how you plan to prefoprm your application. Intermediate Turning Down the Heat in a Cut.

10 rows Feed rate. Calculate the Chip Thinning factors in order to get the Feed per Tooth. SMM SFM X 3048.

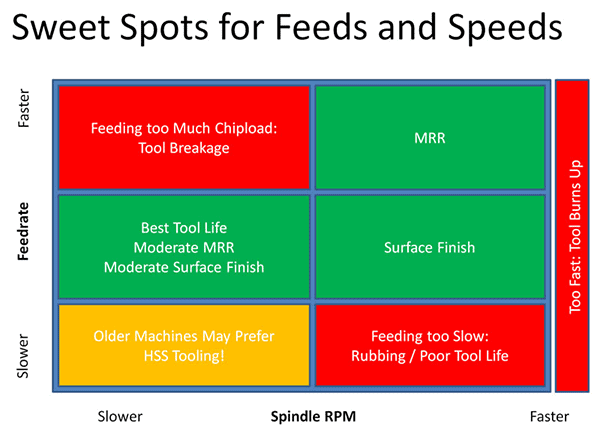

Easy Speeds And Feeds only serves as a starting point and educational site. Coolant and Chip Clearing. Always use the speeds and feeds recommended from your tool manufacturer.

If the material you need is not listed contact. Feeds and speeds are starting recommendations only. Milling Speed and Feeds Calculator Spindle Speed Calculator.

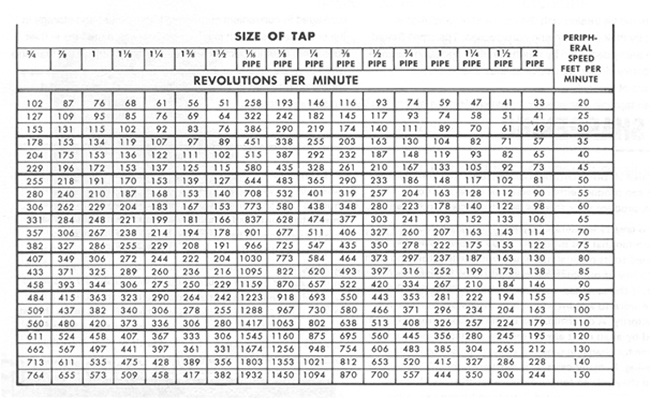

For example a feeds and speeds chart is a 2 dimensional table. The original source is unknown. It supersedes drilling speeds from the first page in.

Feed per tooth IPT. All you need are the speed RPM number of flutes material and tool diameter. Use a state of the art Speeds and Feeds Calculator Toolroom vs Manufacturing Feeds and Speeds.

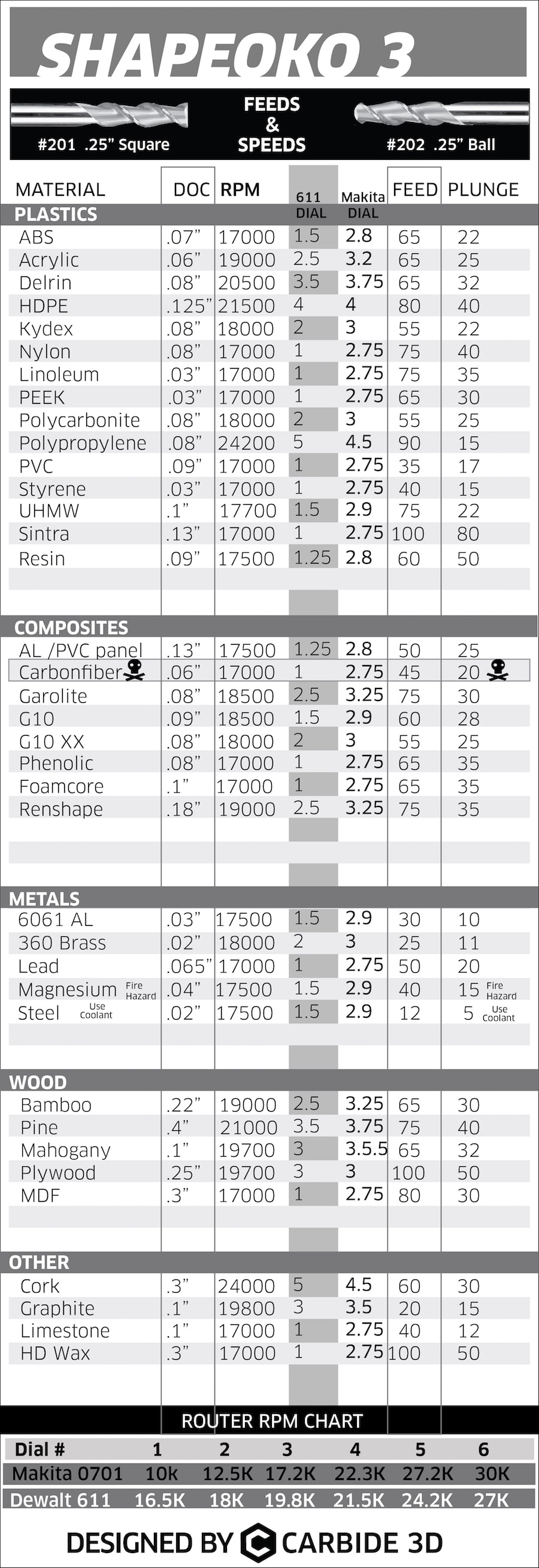

CNC Router bits and CNC router tools are effective only if used in the correct manner. Feed Rate Spindle Speed RPM Number of Flutes Chip Load. Chip Load 500 inches per minutes 15000 RPM x 2 flutes Chip Load 017.

Drilling Speeds and Feeds. Our G-Wizard Feeds and Speeds Calculator covers 60 variables. This chart is posted on the wall in several places in the Machine Shop in 101 CTB.

31 rows End Mill Speeds And Feeds Chart - Uncoated Carbide. Reaming Speeds and Feeds. Do you know the difference between toolroom and manufacturing feeds and speeds.

Feeds and speeds formula. 120 - 180 SFM. That data is important but used by itself its also loaded with limitations.

Number of teeth Cutting feed IPR Cutting speed SFM 12. Tool Diameter inches. It can only cover 2 variables.

Calculate the feeds and speeds needed for CNC cutting tools machines and projects with our free calculator below. Counterboring Speeds and Feeds. Calculation are as follows.

RPM 12 Surface Speed PI Tool Diameter revsmin Feed Rate RPM Chip Load Number of Teeth Flutes inmin Where PI is the constant 3141592654. Tool diameter in π Spindle speed RPM Cutting feed IPR. This chart provides starting parameters for calculating speeds and feeds.

Factors such as machine fixture and tooling rigidity horsepower available coolant. 120 - 180 SFM. Actual feeds and speeds will depend on many variables including machine tool condition rigidity workpiece size and shape tool extension depth of cut etc.

Chip Load Feed Rate inches per minute RPM x number of flutes. The Chip Thinning factors make. Spindle speed RPM Feed rate IPM.

F inmin N rpm frinrev 1500 revmin 0004 inrev. Drill Diameter inches Drill Feed iprd 1 0015-0025 dIn inches per revolution of the drill bit. Best practices for coolant and chip clearing on the mill.

You can rely on data from the Tooling Catalog feeds and speeds chart. Spindle RPM Formula 12 SurfacceSpeed PI CutterDiameter Feed Rate Calculator. First is the formula to find the RPM RPM SFM X 382 diameter of the tool SFM Surface Feet per Minute You can also use the RPM calculator below.