Ra Surface Finish Chart

Metal Casting versus Forging Comparison Chart Comparative Hardness Scales Steel Surface Roughness Surface Roughness Conversion Visual Surface Finish Scales Geometric Dimensioning Tolerancing Symbols Cast Iron Material Comparison Chart Cast Steel Material Comparison Chart.

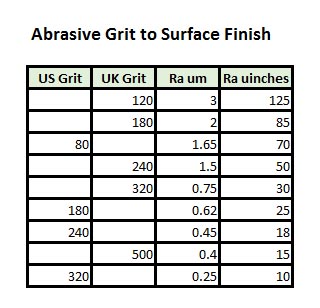

Ra surface finish chart. R a R 1 C l R 2 C l R n C l n. CLA Center Line Average microinches. Grit usa common usa ra ep range uk ra rmax japan rmax approx.

Surface Finish Chart. SURFACE FINISH COMPARISON CHART. This site uses cookies to improve your experience and to help show content that is more relevant to your interests.

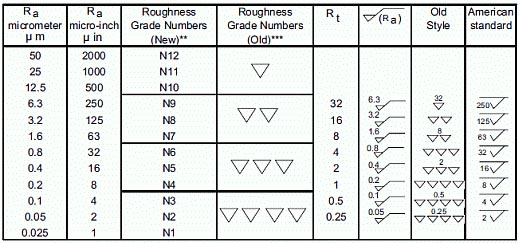

Rt Roughness Total microns. Ra stands for Roughness Average. In past years Ra was also known as Center Line Average CLA or Arithmetic Average AA but today Ra is the most commonly used surface finish parameter in the steel industry.

RA is the arithmetic average deviation of the surface valleys and peaks and is often used to specify the roughness of a machined surface. 13 rows Surface roughness is a calculation of the relative smoothness of a surfaces profile. 4079 Pepin Ave.

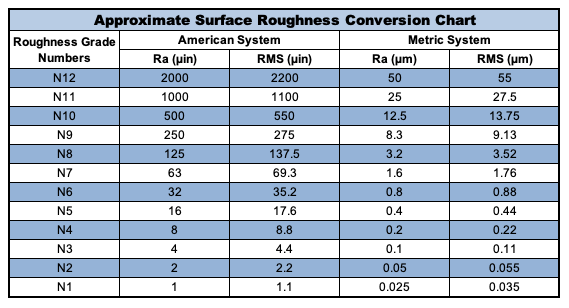

RMS Root Mean Square microinches. SURFACE ROUGHNESS CONVERSION CHART Mactech Inc. Ra Roughness Average in micrometers or microinches RMS Root.

Ra Roughness Average microinches. 13 rows The following charts and tables convert surface finish or roughness between selected industry. Most drawings and prints you see will have a Ra surface.

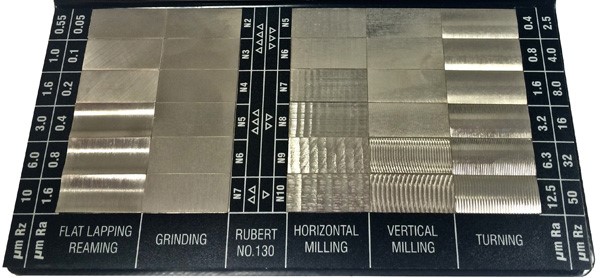

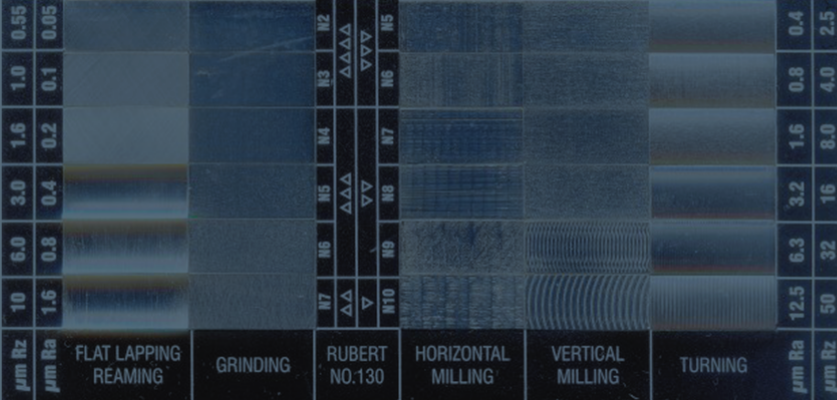

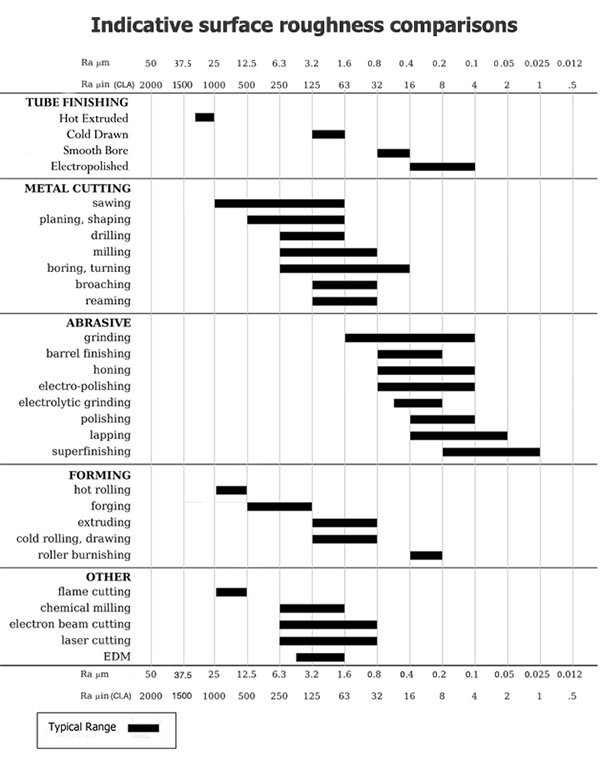

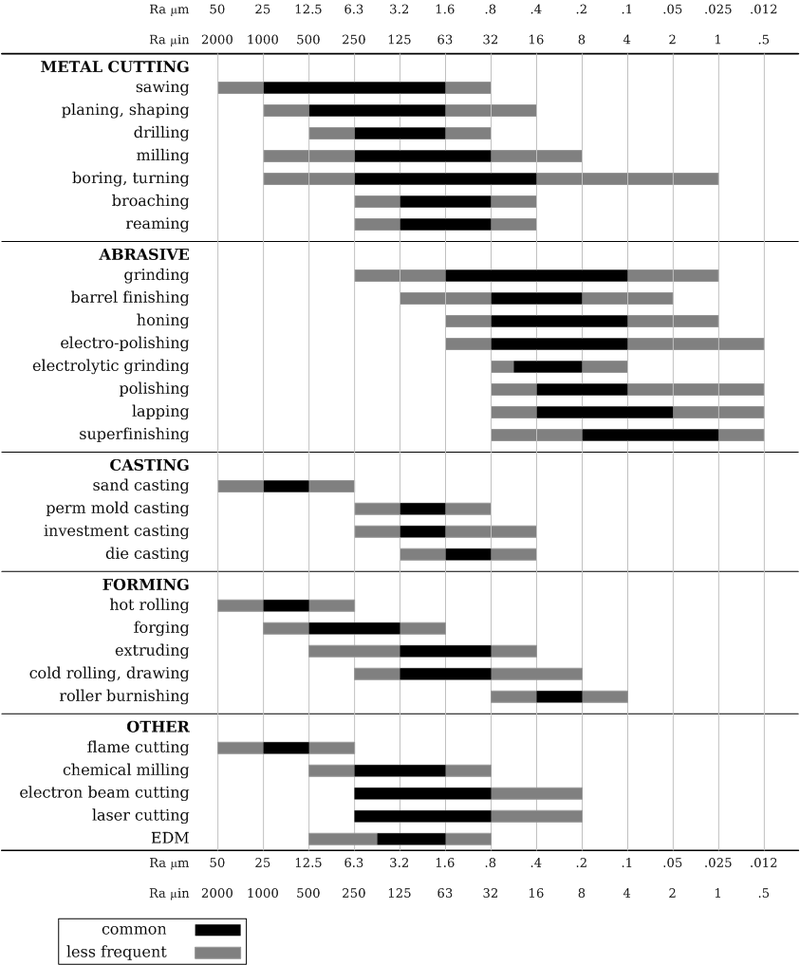

Surface finish in fabrication Average Ra µm Bead blasted 100-600 Bored turned 040-600 Electropolished 010-080 It should be noted that the values in the table are for orientation only and that they vary between different producers and typical surface finish. A surface finish chart such as this could include the following parameters. Ra Surface Finish Chart.

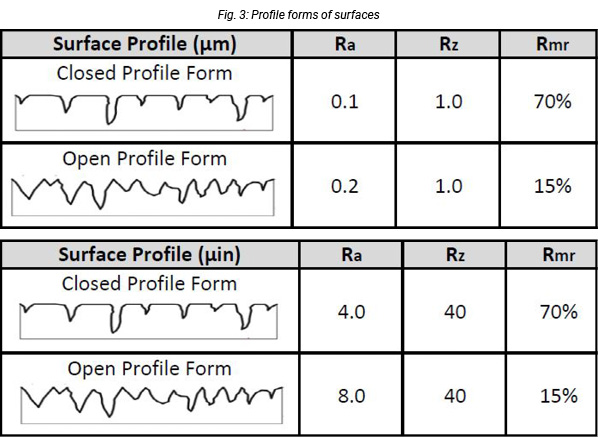

This is a calculation of the average length between all the peaks and valleys or the average height from the mean line of the surface. Rms iso astm std japanese. Ra Roughness Average micrometers.

It is suggested that as concerns surface roughness require-. What Ra measures is the average distance or height of the peaks valleys from the mean line. According to ASME B461 Ra is the arithmetic average of the absolute values of the profile height deviations from the centerline recorded within the evaluation length.

A standard 4 finish could be about 08 32 Ra while a 4 Dairy or Sanitary finish have an. Ra and D are two important surface finish parameters The Surface Finish Units we would use. Red Wing MN 55066 PH.

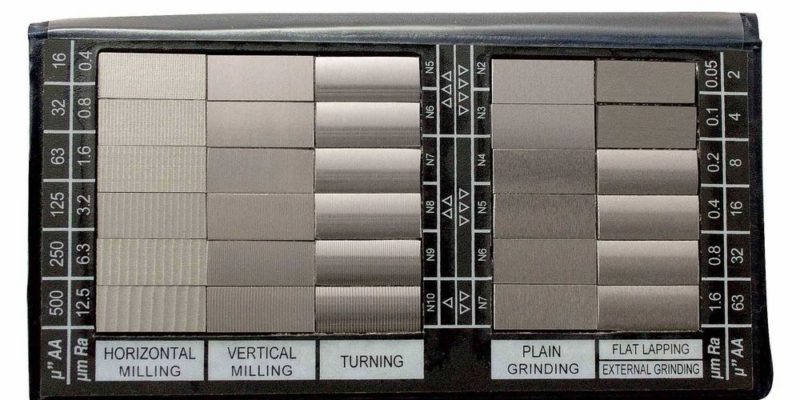

ISO No New ISO Grade Scale Numbers. Contact us here email us or give. Machining surface finish chart comparator method degree Ra Rz RMS As for machining to iron.

Ra Surface finish value in MicrometersMicro-inches. Got questions about how best to achieve the desired finish. RMS is the root mean square average of the profile height deviations from the mean line of the surface and is mostly used for optical surfaces.

The term Micro means millionth. Ra μm AA CLA μinch Conventional symbols Surface description 0025 005 1 2 Super inishing Burnishing diamond paste 01 4 Lapped extremely ine inish perfectly smooth 02 8 Lapped for seal joints 04 16 Ground EDM 08 32 Machined extremely ine inish 16 63 Machined very smooth 32 125 Machined smooth 63 250.