Conduit Bending Chart Pdf

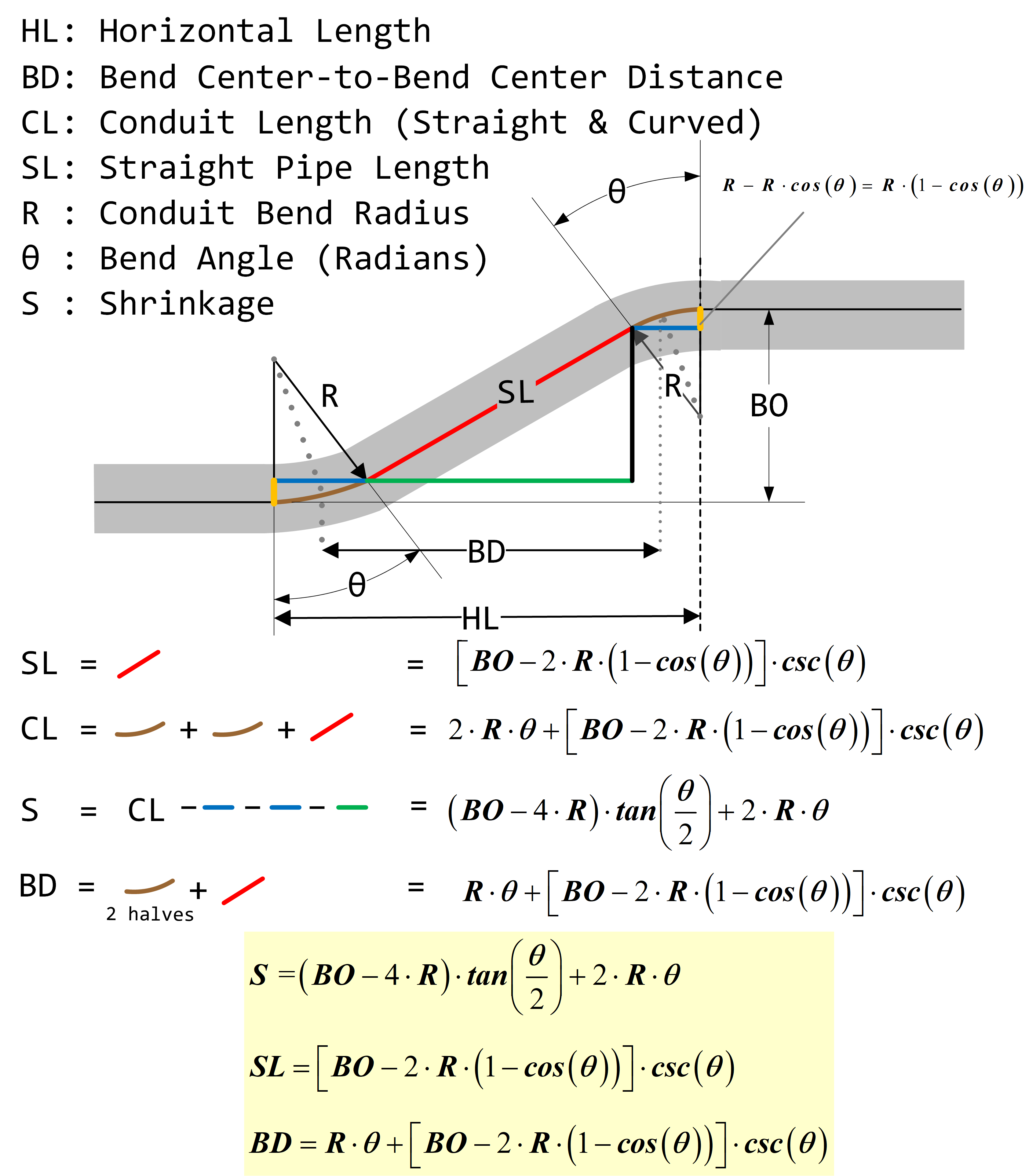

Two identical bends placed in a conduit to change direction or elevation of the pipe run.

Conduit bending chart pdf. Insert the data from fact sheet into the appropriate green column in the bending program. Once the rigid conduit has been adequately heated bend it to the required angle plus 3 extra degrees. This type of bending is suitable for bending electrical conduit and similar light gauge product.

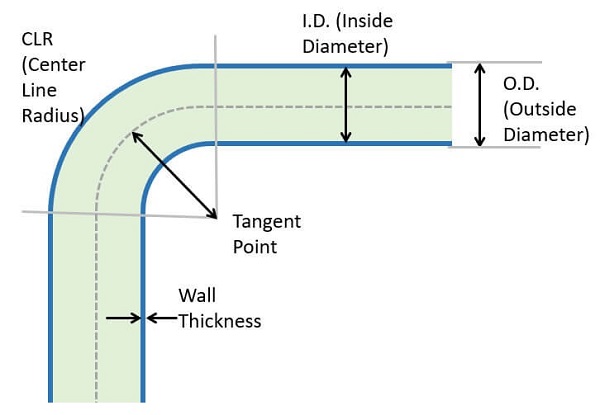

The only tools you need for more complex bends are an angle finder and a cheap scientific-type hand calculator. Press or Ram bending 14 Rotary Draw Bending This is the most commonly used style of bender for bending pipe and tube where maintaining a good finish and constant diameter is important. Cal bending radius but is displaced indirection of the bending axis.

A mark used to locate the edge of an obstruction for bending saddles. Measure and mark your conduit the same distance mark B. To bend a 90 bend using 3 - 30 bends as shown.

Rotary draw benders RDB are precise in that they bend using tooling or die. You can calculate for 10 degree bends which makes things somewhat easier as you have less bends. The following illustrations and instructions show the most common bends.

Brace pipe under your shoulder now bend the pipe down 10. The electrician must use caution when bending raceways to make sure that it maintains its round shape throughout the bent portion of the raceway in. Professional conduit bending tools.

A proper bend is made by rolling the conduit about the bender in the conduits cradle using all foot pressure. Check the markings on the frame. Use the same technique for a conduit run across the floor or ceiling which turns up or down a wall.

Multiply side A of by the cosecant of 30 that equals side C 2 X 2 4 Multiply side A of by the cosecant of 30 that equals side C 1 12 X 2 3 Multiply the tangent of 12 the bend angle by the OD. The math and formulas that make up a simple conduit-bending guide are actually quite simple and easily learned. Outside diameter of a pipe.

Slide the pipe down to the second mark to the arrow and Rotate the pipe 180 upside down bend pipe back to a 10 angle. Use the correct size bender for the conduit size being bent. 555C 555CX 555DX can bend 12 34.

See the Special Bending Information Chart for precise bending dimensions. The resting condition of the conduit is to be at the final angle desired. Line up Y with arrow on bender.

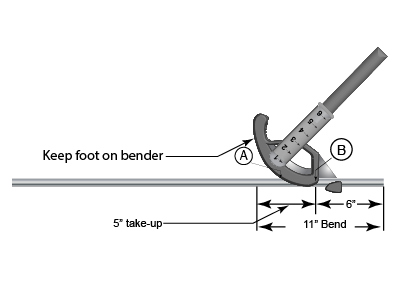

The math and formulas that make up a simple conduit-bending guide are actually quite simple and easily learned. Put foot on the floor bracing the end of the bender with your toes. Line up the Arrow on the bender with the mark on the conduit and bend to 90.

Two of the three holes in the back of the ratchet handle are for the locating pin on the frame. For this reason every pipe suffers a certain elongation during the bending process but it is possible to approximately determine the corresponding cutting length with the help of mathematical calculation. For commercial industrial and utility usage Allied PVC conduit and duct is proven durable and effective for years of maintenance-free performance in underground encased and exposed applications in accordance with the National Electrical Code.

Ive included a fractionsdecimal conversion chart for reference on Page 14. This document will step the beginner through the five main bends that are used by electricians. 1818 1818R 555C 555CX 555DX can also bend Stainless Steel Rigid conduit in the same size conduit ranges as steel Rigid conduit using the Rigid shoe group.

Conduit and fittings and PVC utility duct. For Stainless Steel EMT conduit bending 855GX can bend 1-2. The end of the conduit Y.

In this case 14 minus 6 8. Some over bending may be required to allow for spring back of the conduit. Find the chart that corresponds to the size of conduit selected in Step 1.

The only tools you need for more complex bends are an angle finder and a cheap scientific-type hand calculator or in todays world a smartphone with a calculator. Mark the conduit 8 from the end. The relative size of the bent portion of a pipe.

The IDEALbender indicates stubs 6 to. When bending 12 34 or 1 conduit the lower left hole is used. Allied Tube Conduit offers a complete line of rigid PVC.

The shortest part of. Radius x 157 divide by 18 to get the spacing between bends for one quarter of a circle. And 1818 1818T can bend 34 1 with respective.

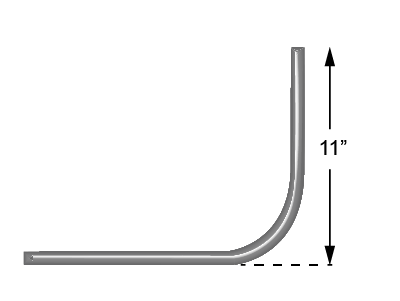

Stubs HEIGHT Y MARK ANGLE 1. The stress-free layer is positioned even further inside it is the layer which shows no longitudinal. The rigid conduit must be heated to ap-proximately 260F in order to bend without kinking.

Table 1 Measure and mark distance on the conduit from a fixed point X to the back of the 90 bend point Y. Conduit Size EMT Deduct Rigid or IMC Deduct 12 127 mm 5 127 cm 6 152 cm 34. CONDUIT Bend Mark Stub A Length B Cut Length Travel Deduct Gain B to B 34 IMC 6375 15500 35500 47500 9000 9125 3500 5625 Select the conduit size and type Tan cell drop down box in the bending program.

The amount a conduit reduces in total length after an offset is bent. Align Y with B or on bender and make a 90 bend. They have a specific formula to calculate the concentric bending of the conduit.

Go to the top of the page. Simply subtract the take-up or 6 from the finished stub height. No need to input data into the Back to Back column the.

Any electrician bending large conduit should already have an angle finder as without a hand bender to tell the angle being bent an angle. When bending 114 1 or 2 conduit the top center hole is. Heat a length of conduit equal to approximately 10 times the rigid conduit nominal diameter.

Determine the height of stub and the angle of bend. A back-to-back bend produces a U shape in a single length of conduit. Consider making a 14 stub using a 34EMT conduit.

The lower hole is used when bending 1 14 1 2 and 2 conduit. BENDING CONDUIT TUBING USING HAND BENDERS The ability to bend conduit and tubing is a requirement for all electricians.