Concrete Curing Temperature Chart

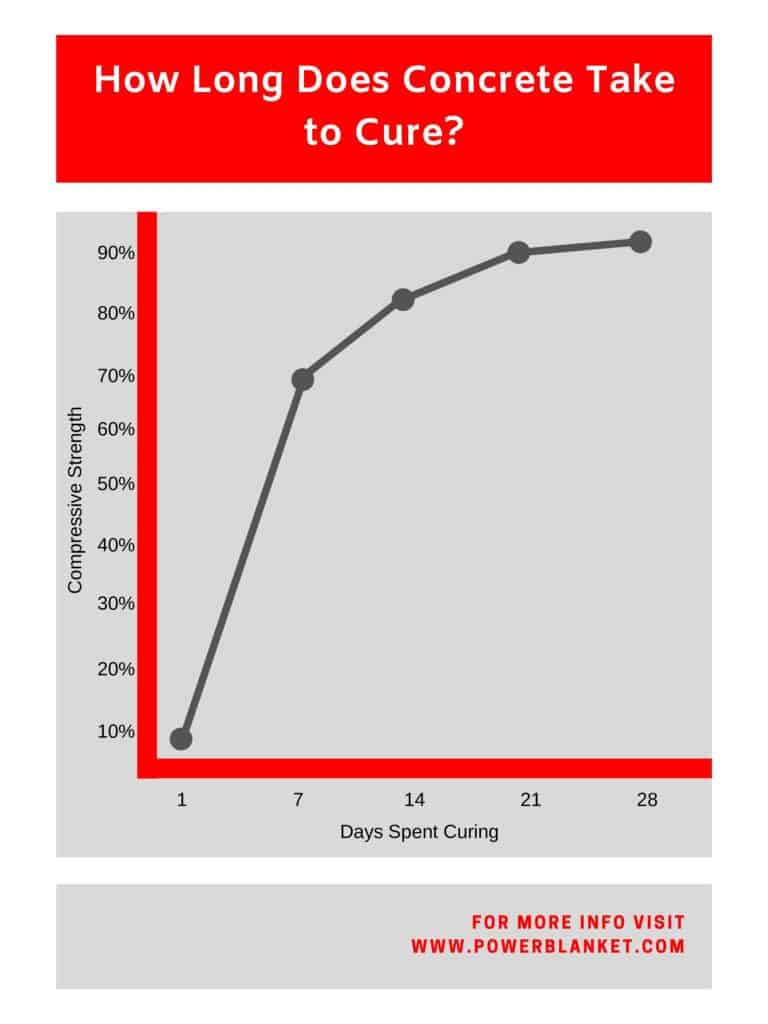

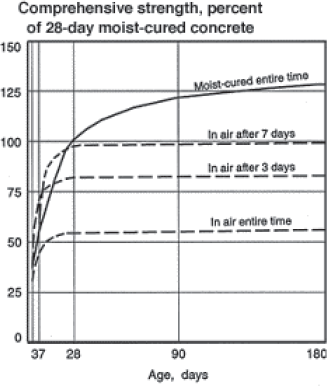

Keeping the concrete moist at certain temperatures and for certain amounts of time is key to both accelerating the curing process and further strengthening the concrete.

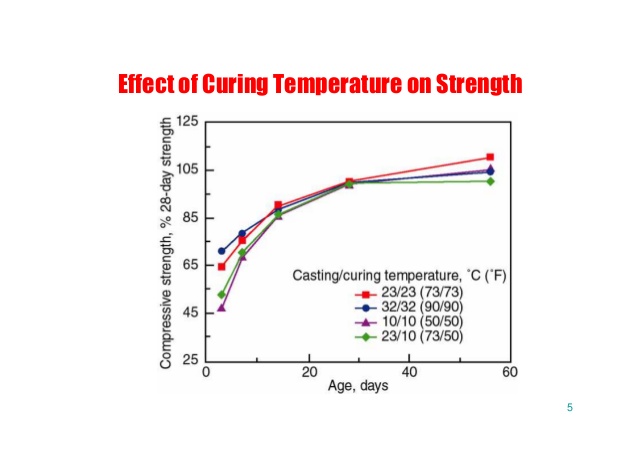

Concrete curing temperature chart. Draining water on the concrete surface cures the concrete. The four test con- ditions included concrete cast and cured at 23C 73F concrete cast and cured at 32C 90F concrete cast andcured at 10C 50F concrete cast at 23C 73F and cured at 10C 50F. Make sure the concrete is maintaining a temperature of at least 40 degrees for its curing period.

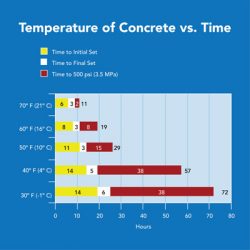

To be effective wet curing must last at least 7 days. Moisture-sensitive flooring sensors for mass concrete curing and new curing monitoring techniques have been added or enhanced in this document. Never pour concrete over frozen ground snow or ice.

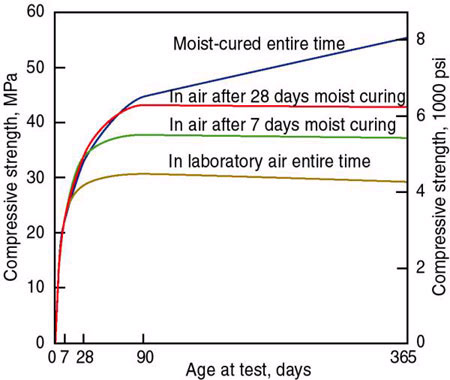

900-1800 mm 72 in. 300 mm 12-36 in. The first graph is simply compressive strength development versus age for each test condition.

The main components which need to be taken care of are moisture heat and time during the curing process. Of curing concrete and may be applied to freshly placed concrete or that which has been partially cured by some other means. For most concrete structures the curing period at temperatures above 5º C 40º F should be a minimum of 7 days or until 70 of the specified compressive or flexural strength is attained.

12Curing Curing is an action taken to maintain moisture and temperature. 300-900 mm 36-72 in. Fill the tanks with water that has been saturated with lime calcium hydroxide aka.

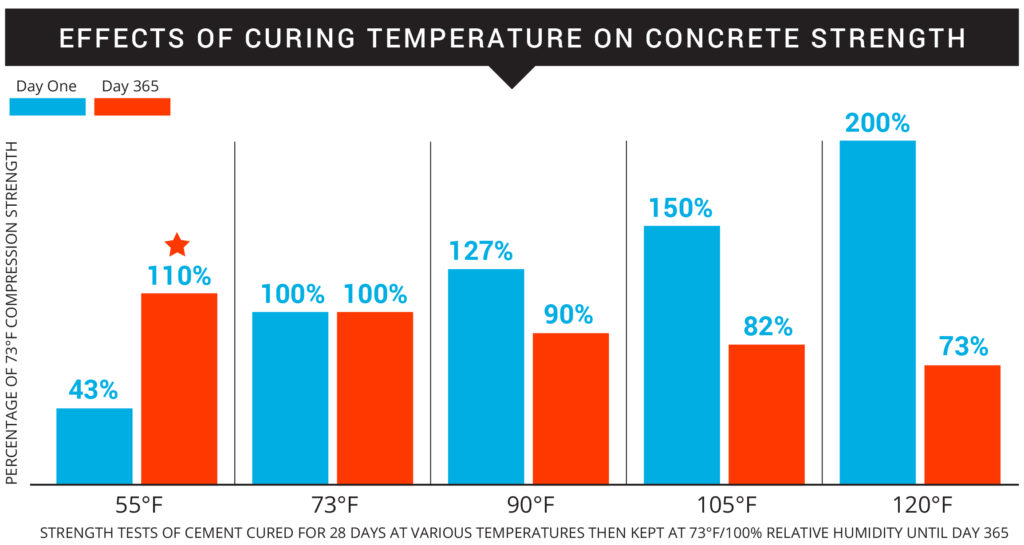

The temperature of the concrete is whats important here not necessarily the air temperature. The same time raise the temperature of the concrete thereby increasing the rate of strength gain. However they may affect the bond between.

Table 1 - Recommended concrete temperatures Section Size minimum dimension. The best way to cure concrete. Below about 40 F it virtually stops.

The period can be reduced to 3 days if high early strength concrete is used and the temperature is above 10º C 50º F. 9 rows However proper cold weather concrete curing will enhance concrete strength development. Alternate wetting and drying of the surface actually damages the concrete.

The temperature of the concrete as placed should be above 40 degrees Fahrenheit using methods described above however the duration of heating is dependent on the type of service for the concrete ranging from one day for high-early strength concrete that is not exposed to freeze-thaw events during service to 20 days or more for a concrete element that would carry large. Maintain concrete curing temperature above 4 C for at least four additional days after the use of insulation blankets or heated enclosures. This method is typically used for precast concrete products and is outside the scope of this data sheet.

Procedure for curing of concrete. Water cooler than 50C is not suitable for curing concrete. The temperature of the solution in the tanks must also be monitored.

Concrete temperature under specific environmental condi-tions are addressed in greater detail in ACI 305R ACI 306R ACI 301 and ACI 318. Concrete Temperature Requirements Section size minimum dimension in. Concrete curing takes on many different forms and thus there are different attitudes processes and yes temperaturesRH levels that are necessary for curing specific concrete in specific.

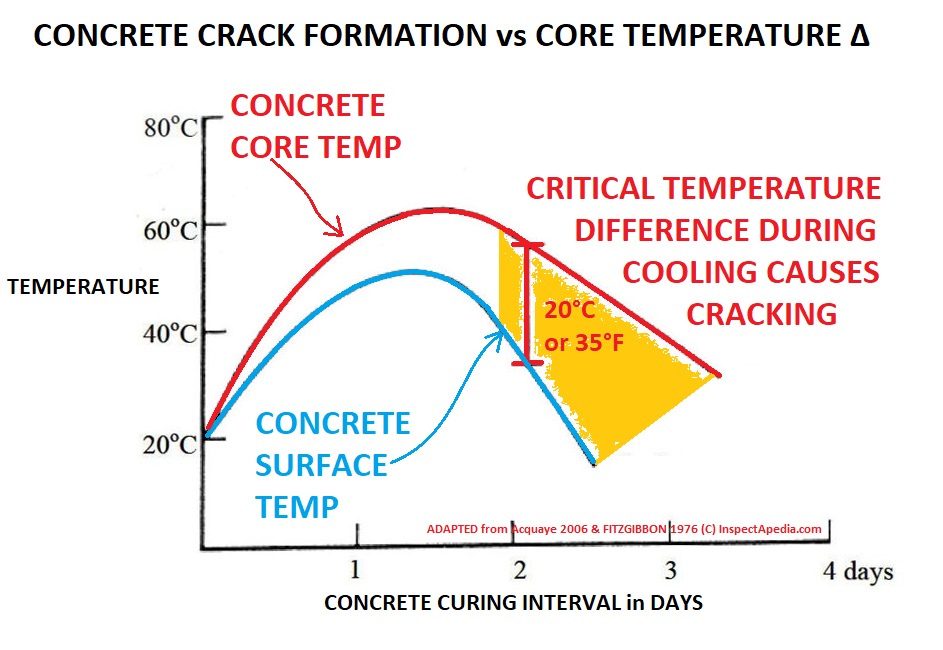

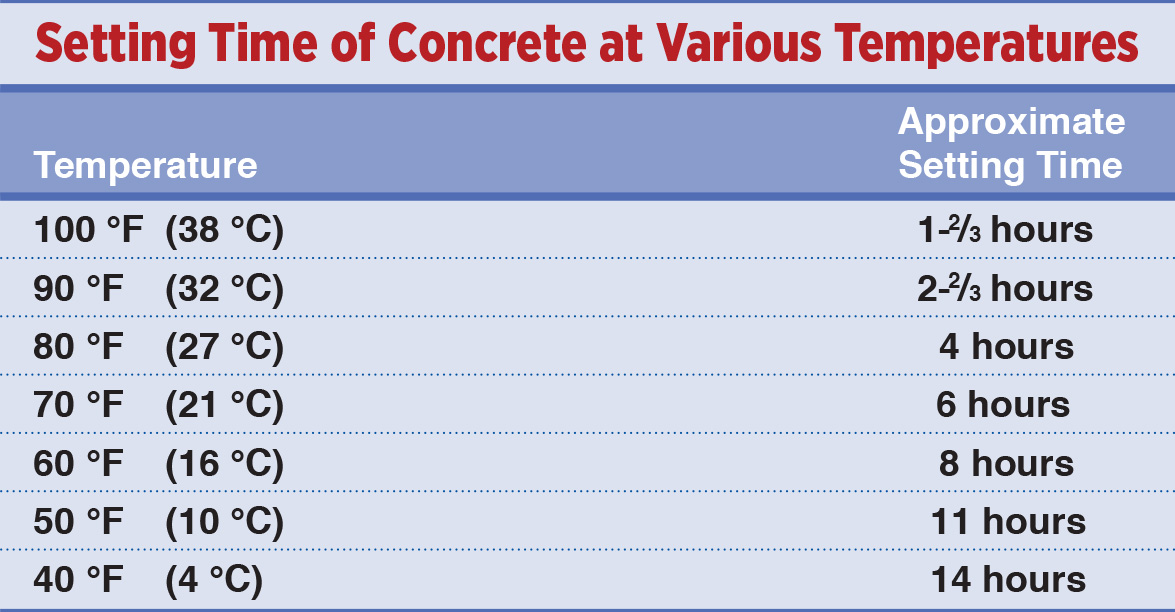

As active heating is discontinued guard against the concrete cooling too rapidly. 1800 mm Air temperature Minimum concrete temperature as placed and maintained 55 F 13 C 50 F 10 C 45 7 C 40 F 5 C Minimum concrete temperature as mixed for indicated air temperature. At 100F it can take less than 2 hours to set 4 hours at 80F 8 hours at 60F and up to 19 hours at 30F.

This can be done by gradually lowering the temperatures within an enclosure or by covering the concrete with insulating blankets. Temperature affects setting time with concrete setting up more quickly the warmer the air and ground temperature. Below about 50 F hydration slows down a lot.

As fresh concrete gets cooler the hydration reaction slows down. As the hydration reaction in concrete expels heat and keep concrete warm Using cold water less than 50C on concrete may lead to cracking and failing. The other important aspect of curing is temperature-the concrete cant be too cold or too hot.

In colder temperatures it will take longer for concrete to set. It is important that the concrete not be allowed to dry between soakings. Should not be used when temperatures are expect-ed to go below 50F prior to drying because they will not form an effective film at lower.

Maintain concrete curing temperatures above 10 C 50 F for three to seven days by using fresh concrete. Curing of cement concrete is defined as the process of maintaining the moisture and temperature conditions of concrete for hydration reaction to normally so that concrete develops hardened properties over time.