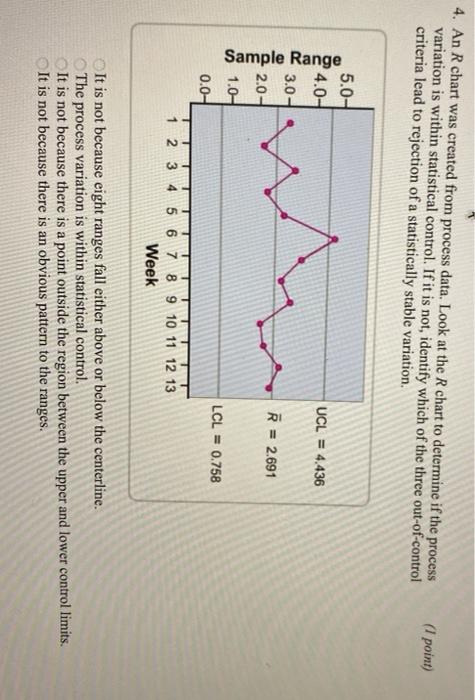

A Point Which Is Outside Of The Lower Control Limit On An R-chart:

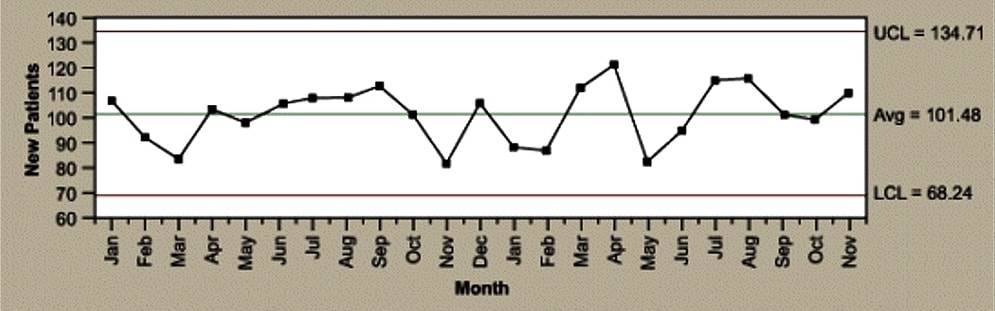

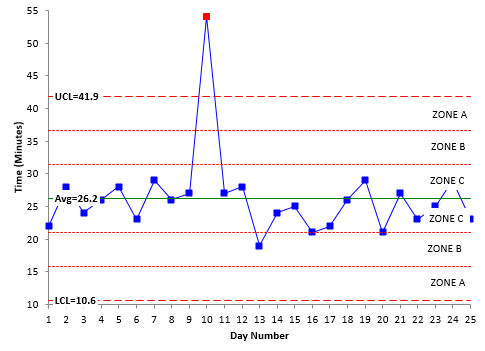

When a point is outside these established control limits it indicates that the mean or variation of the process is out -of-control.

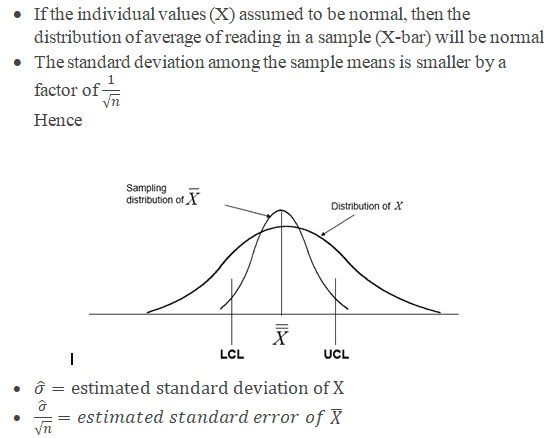

A point which is outside of the lower control limit on an r-chart:. The X bar chart control limits are derived from the R bar average range values if the values are out of control in R chart that means the X bar chart control limits are not accurate. There is no Lower Control Limit for the Range Chart if the subgroup size is 6 or less. An assignable cause is suspected whenever.

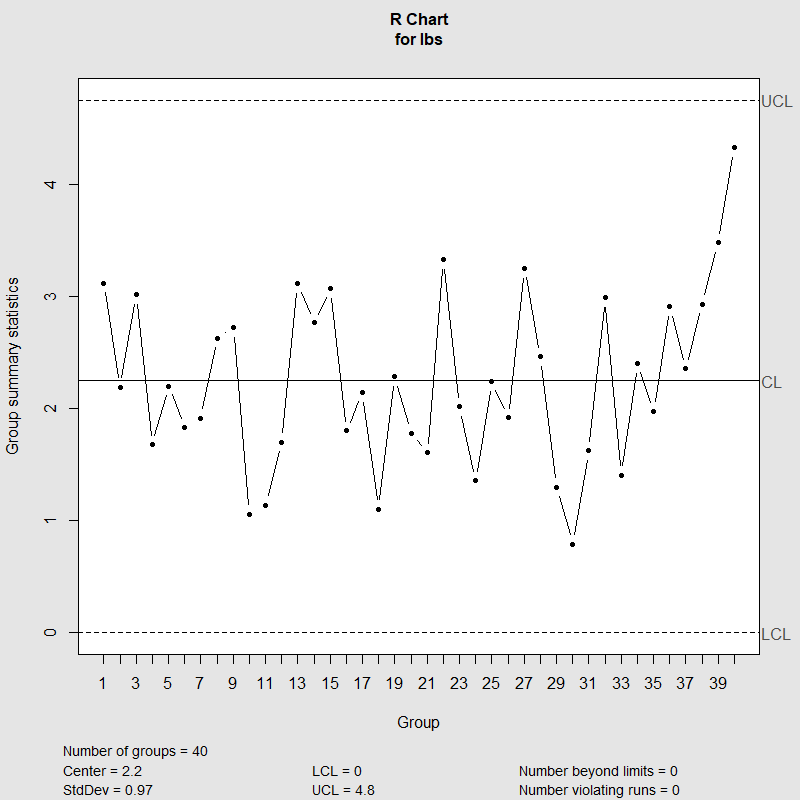

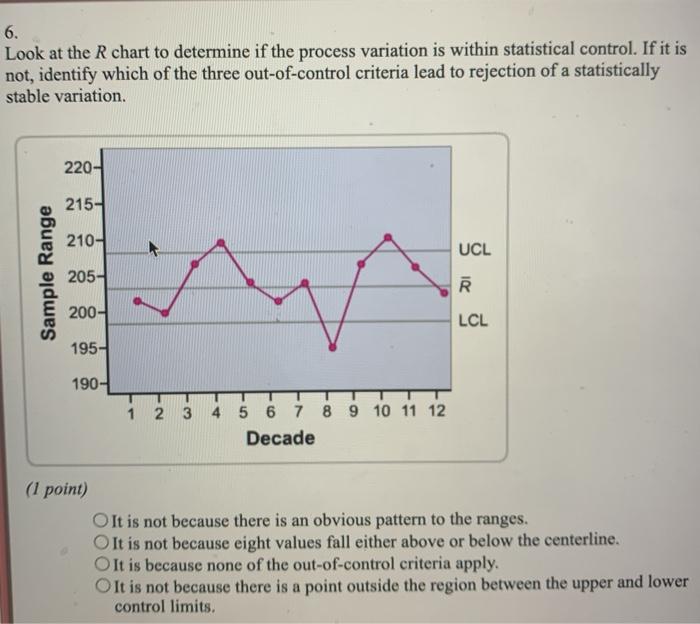

This chart must exhibit control in order to make conclusions on the Xbar chart. The Lower Control Limit LCL 3 sigma below the center line 22131. The R chart is the control chart for the subgroup ranges.

When a data point experimental variable or test falls outside the limits of the control chart it is necessary to identify a reason for the variation. The department foreman is advised to stop the process. If the subgroup size is between 7 and 10 select the appropriate constant called D3 and multiply by R-bar to determine the Lower Control Limit for the Range Chart.

If the points are out of control in R chart then stop the process. Is impossible since the lower limit is always zero. LCLR R-bar x D3.

On a control chart the lower control limit is a line below the centerline that indicates the number below which any individual data point would be considered out of statistical control due to special cause variation. Identify the special cause and address the issue. Should be ignored because it signifies very low process variation.

A point that is outside of the lower control limit on a control chart Multiple Choice is an indication that no cause of variation is present should be dismissed because it represents better-than-average quality suggests that the process output is nonrandom and should be investigated impossible since the lower limit is always zero. If you are looking at a chart pair X-bar and R X-bar and s or X and MR look at both charts. Should be ignored unless another point is outside that limit.

The purpose of control chart is to. Process level is out of control. Points falling outside the control limits may be the result of a special cause that was corrected quickly either intentionally or unintentionally.

If so and if chance causes alone were present the probability of a point falling above the upper limit would be one out of a thousand and similarly a point falling below the lower limit would be one out of a thousand. The decision indicates that. I know it is due to the overall measurement system variation.

A person making a spot check picks out two shafts measures them accurately and plots the average value on the X-bar and R charts. Is an indication that no cause of variation is present. It is typically set to three standard deviations below the centerline for charts plotting central tendency and some multiple of the centerline for charts plotting variation.

It may also point to an intermittent problem. Test values that fall outside limits are labeled not equivalent and further chemical characterization tests are needed to determine the effect of the change. Is an indication that no process variation is present.

Should be investigated because an assignable cause of variation might be present. The Upper Control Limit UCL 3 sigma above the center line 23769. UCL R R-bar x D4 Plot the Upper Control Limit on the R chart.

Is impossible because the lower limit is always zero. A point which is outside of the lower control limit on an R-chart. Outside the limitations of UCL and LCL the quality measured is considered as abnormal and requires intervention in the relevant process.

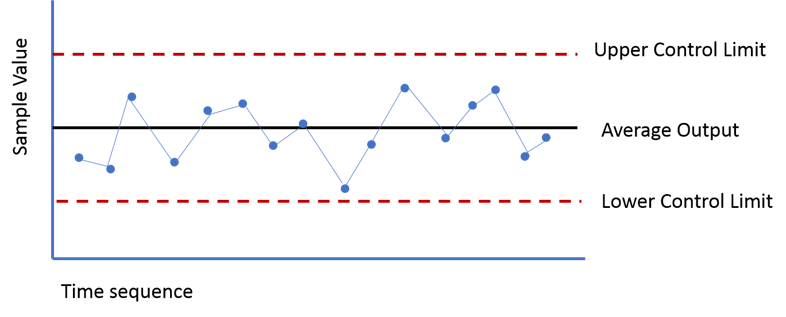

The point falls just outside the control limits. Once the control limits have been established of the X -bar and R charts these limits may be used to monitor the mean and variation of the process going forward. Chart demonstrating basis of control chart Why control charts work The control limits as pictured in the graph might be 0001 probability limits.

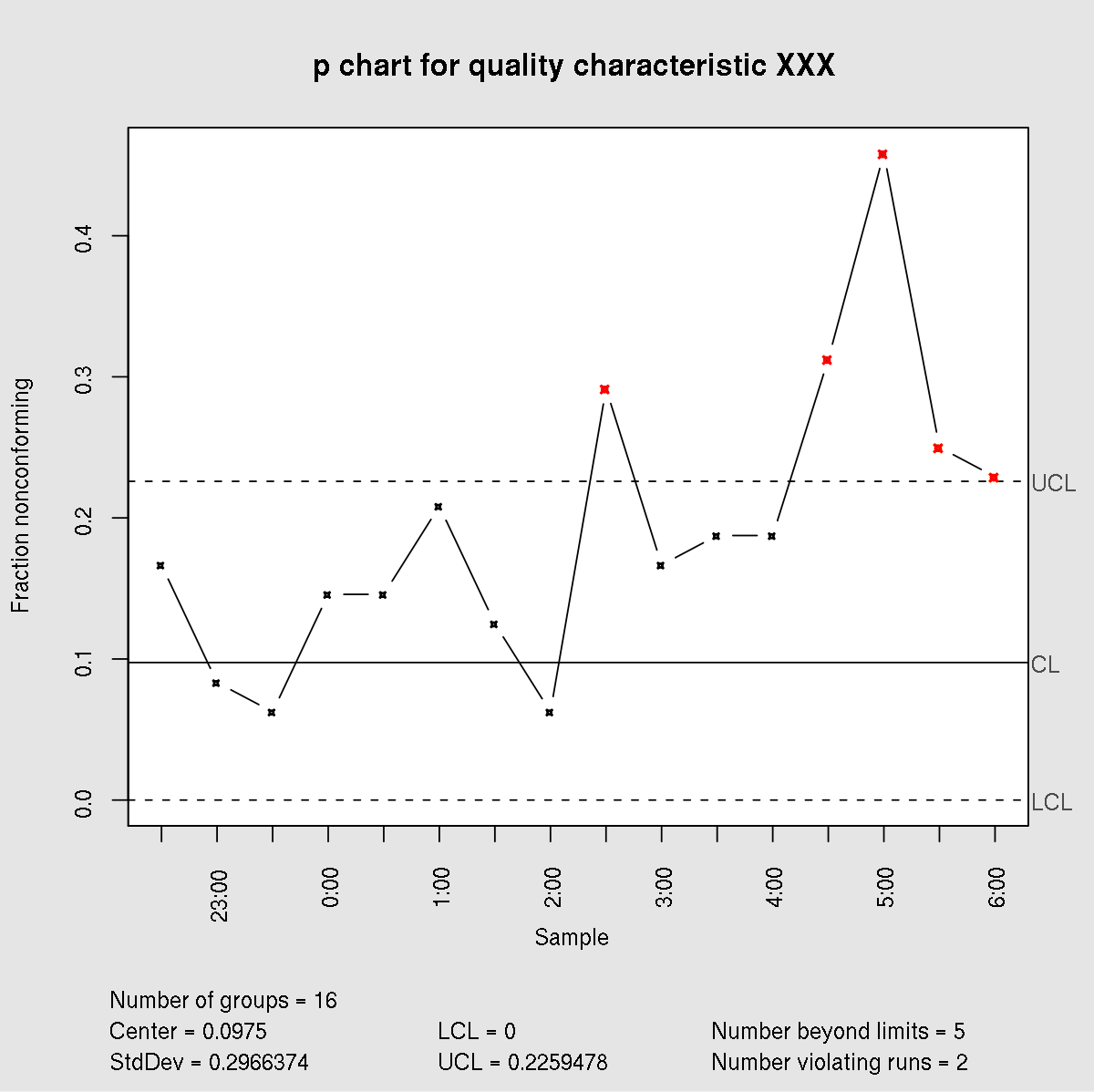

A control chart used to monitor the number of defects per unit is the. The Upper Control Limit UCL and the Lower Control Limit LCL form a corridor within which a quality characteristic meets the desired value or a normal deviation. A point which is outside of the lower control limit on an R-chart.

When points on a control chart move outside the upper or lower control limit the process is said to be out of control As long as the points are within control limits the process is in control. A plot below the lower control limit on the range chart. They are used to determine whether a process is in or out of control.

Control charts are one of the most popular SPC tools used by manufacturers. A point which is outside of the lower control limit on an R-chart. We would be searching for.

Answered expert verified.